This January, I took the train from San Francisco to Sacramento to visit California Cultured, a company that turns cocoa tree cells into flavanol-rich, contaminant-free, eco-friendly, and irresistible cocoa. Not only did I get to see the whole process from cell to chocolate, but I actually had a bit myself!

The Official Biopunk Tour includes a brief visit to three rooms. First, the Hell of Chocolate, where we’ll explore some reasons why there’s a need for lab-grown things in the first place. Next, there’s Da Lab, where I’ll show you how CaCultured practices Green-Clean-Lean Biotech to go from cocoa tree cells to chocolate.

BSL5, the last room, includes a full video tour of California Cultured’s lab and interview with CEO and founder, Alan Perlstein. Since this Biopunk Tour is not sponsored by CaCultured or any other company, BSL5 is reserved for paid subscribers only. Get your own mighty GOLDEN TICKET by upgrading to paid:

The hell of chocolate: don’t drown.

As you’re surely aware, futures markets have seen a 300% increase in the price of cacao since 2021, and 2024 marked the third year in a row in which supply was shorter than demand.

Even this year’s Valentine’s, prices were still up by 20%. Companies like Hershey and Mondelez have considered hiking product prices, and others like Mars have resorted to decreasing the size of their chocolates while selling them for the same price.

Blame it on biology! The cacao swollen shoot virus (CSSV) uses Mealybugs to move between trees. Since the bugs are sensitive to drought or excessive rainfall, climate disasters like El Niño — which impacted 81% of the Western North region of Ghana — can increase the spread of pests. Within two years, CSSV can decrease yields by half in Côte d’Ivoire and Ghana, where 60% of the world’s cocoa is produced.

Despite widespread trials, chemical control has been inconsistent, expensive, and environmentally problematic, especially for smallholder farmers in Côte d’Ivoire and Ghana. So far, the only way to stop the spread has been to cut the infected trees and plant new ones, which can take four years to grow fruit.

The Cocobod (cocoa board) is the only organization allowed to market and export beans in Africa. It sets fixed prices at the beginning of the season, so farmers get the same regardless of price volatility (in this case, a net loss). Even at these prices, Ghana only captures about 2% of the $100 billion dollar chocolate industry, and virtually all of the world’s chocolate gets consumed elsewhere.

Rich in gold, illegal mining operators have intimidated African cacao farmers into selling their land. These practices increase the risk of cadmium and lead root uptake as the crop grows, as well as during harvesting and drying. In South America too, cadmium contamination can be caused by fertilizers and water.

No wonder that, out of 23 brands tested by Consumer Reports, only 4 had safe levels of both heavy metals. Then, you can get Bryan Johnsons selling clean chocolate at a premium, because products noted as “organic” were actually more likely to display higher levels of heavy metals.

🎮 Da Lab: Grow everything, everywhere, all at once

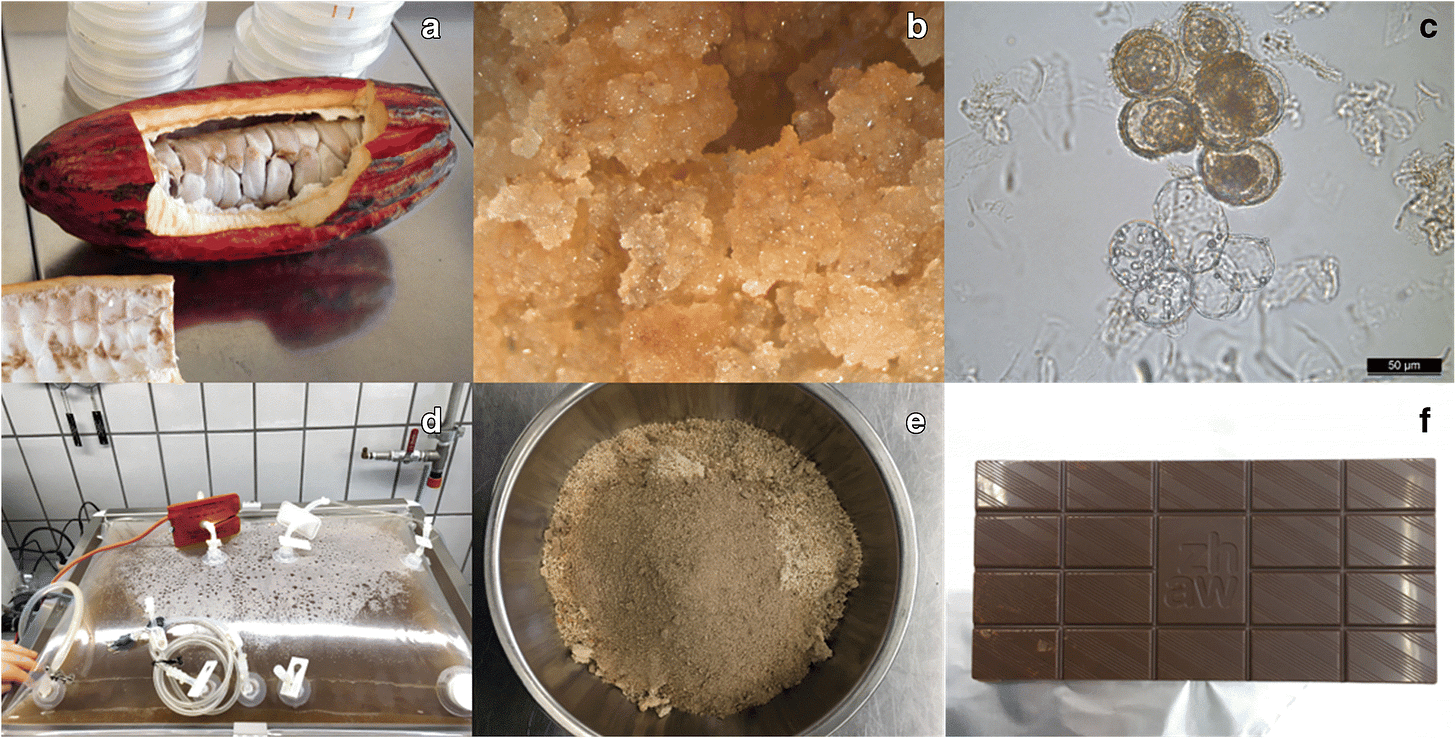

In nature, cacao trees begin to produce between 20 and 30 cocoa pods every year, when they’re 4 to 5 years old. Each pod contains 20 to 60 beans which are harvested, dried, fermented, and roasted.

During fermentation, the pulp that covers them is removed, so ethanol and acids from microbial metabolism diffuse into the seed. The combination of heat, low pH, and oxygen contributes to protein and polyphenol breakdown.

Next, roasting stops enzymatic activity, reduces moisture content, drives off volatile acids, and ultimately develops a complex aromatic and flavor profile of over 600 compounds.

At the factory, the beans are roasted and are cracked to break the shells and release the nibs (the edible part). These nibs are ground into cocoa liquor, which can be blended with other ingredients like milk. This mixture is refined to reduce particle size, tempered, and solidified in molds.

In Da Lab, the first step is to find rare and exotic cocoa pods from around the world. We open the pod, take a cutting from a bean, and put it on a petri dish with media specifically formulated to induce calli growth (think of calli like plant stem cells).

After about 4 weeks, calli cells are formed. After 6 weeks, some of those can be placed in proliferation media in ever-larger vessels. CaCultured constantly monitors media changes, calli growth rate, flavors, and environmental conditions, so they can select the best-performing cells in each dish and flask.

Let’s be real: growing things in a lab is not magically more “sustainable” than growing them in fields. In fact, it may be the complete opposite at first, if you’re not careful, honey: making steel for bioreactors energy-intensive, so is sterilizing the bioreactors and all of the other instruments; not to mention some of the media ingredients still come from plants grown in a field with fertilizers, and all of the plastic used and disposed of in a biotech lab.

Throughout the tour, Alan demonstrated three principles for how they think of cellular agriculture at California Cultured: Green-Clean-Lean Biotech. What may otherwise be known as “a truly circular bioeconomy”.

In a first instance, they substitute expensive chemical reagents for extracts from plants cultivated nearby, mainly as carbon sources for their growth media. This is commonplace for tissue culture labs that want to save a few bucks. For other media ingredients, CaCultured partners with large producers to reduce costs and de-risk their supply chain.

When it comes to scaling up, CaCultured understands that they can’t bringing this new cocoa to the market using the same heavy, expensive, and energy-intensive equipment their biopharma incumbents are used to. That’s why they’re building their own biomanufacturing infrastructure: their plastic reusable bioreactors can be sterilized with low energy chemical cleaning instead of steam, saving energy and time.

As an interesting fact, researchers from Zurich University of Applied Sciences, found how bioreactor design can have an important influence in the final taste of chocolate by eliciting the production of different secondary metabolites. For instance, if the cells are shaken, they produce more fruity aromas; in the presence of a lot of air, like in an airlift reactor, they produce more floral compounds.

After 3-4 days, we can harvest our flavonol-rich cells from the bioreactors. If used as a nutritional supplement, we can simply dry in a kitchen dehydrator (#LeanBiotech). If the goal is to make chocolate, yeast and microbes are added to ferment the beans and create the flavors people love. The rest of the process is done per usual.

BSL5: the industrialization of biology

“Over the next five years, every single country and company is going to want to have locally produced products and ingredients to avoid issues with labor, transport, pollution. People will prefer this to be done cleanly, safely and affordably, which is what domestic bioproduction can do” — Alan Perlstein.

Listen to this episode with a 7-day free trial

Subscribe to Biopunk to listen to this post and get 7 days of free access to the full post archives.